Understanding Castor Oil Derivatives: Industrial Value, Processing Logic, and Global Demand

Castor oil derivatives play a critical role in modern industrial chemistry due to their unique molecular structure, renewable origin, and functional versatility. Unlike many vegetable oil derivatives, castor-based chemicals contain inherent hydroxyl functionality, enabling controlled chemical modification and performance tuning across multiple industries.

This article explains why castor oil derivatives exist, how they differ, and why global industries rely on them.

Why Castor Oil Is a Unique Chemical Feedstock

Castor oil is derived from Ricinus communis seeds and is distinguished by its high ricinoleic acid content. The presence of a hydroxyl group on the fatty acid chain makes castor oil chemically reactive compared to most other vegetable oils.

This allows castor oil to be converted into:

-

Fatty acids

-

Hydrogenated products

-

Esters

-

Dehydrated oils

-

Polymer intermediates

As a result, castor oil serves not only as a base oil but also as a platform molecule for specialty chemicals.

Major Categories of Castor Oil Derivatives

Fatty Acids & Esters

Derivatives such as ricinoleic acid, methyl ricinolate, and methyl 12-hydroxy stearate are used where controlled polarity, lower acidity, and predictable reactivity are required. These materials are widely used as intermediates in lubricants, polymers, coatings, and specialty formulations.

Hydrogenated & Structured Products

Hydrogenated castor oil and 12-hydroxy stearic acid provide solid structure, thermal stability, and thickening behavior, supporting applications in greases, cosmetics, pharmaceuticals, and polymer systems.

Modified Oils

Products such as dehydrated castor oil and blown castor oil are chemically modified to enhance drying behavior, viscosity, film strength, and adhesion, making them essential in coatings, inks, and resin manufacturing.

How Castor Oil Derivatives Are Manufactured (High-Level View)

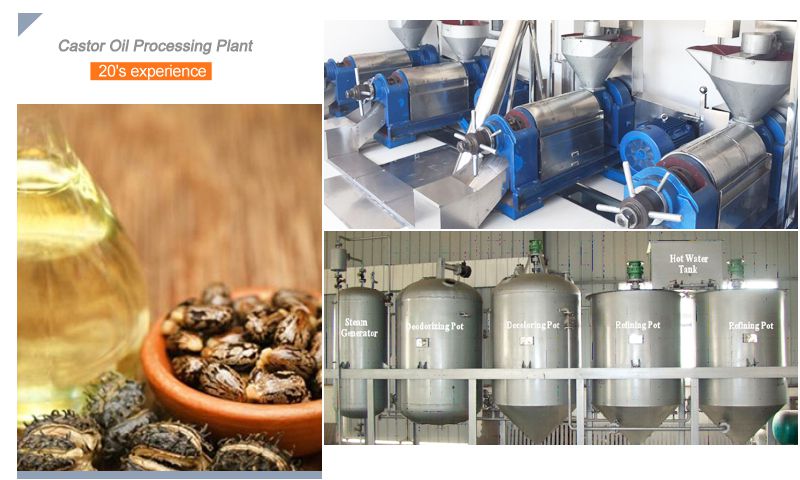

While each derivative has a specific pathway, most follow a structured flow:

-

Castor oil extraction and refining

-

Targeted chemical modification (hydrogenation, dehydration, esterification, oxidation)

-

Purification and finishing

-

Batch-wise quality verification

The goal is functional transformation, not commodity processing—each step is designed to deliver predictable performance in downstream applications.

Key Industrial Sectors Using Castor Oil Derivatives

Castor derivatives are not consumer-facing ingredients; they are performance enablers in industrial systems.

-

Lubricants & Greases – viscosity control, thickening, lubricity

-

Polymers & Resins – renewable intermediates, flexibility, reactivity

-

Paints, Coatings & Inks – drying behavior, film formation

-

Pharmaceuticals – excipients, structuring agents

-

Cosmetics & Personal Care – texture, stability, controlled feel

-

Agrochemicals & Specialty Chemicals – formulation stability

Why India Is the Global Hub for Castor Oil Derivatives

India dominates global castor oil production due to agronomic suitability, established processing infrastructure, and export-oriented supply chains.

Structural Advantages

-

Largest castor seed producer globally

-

Concentrated processing ecosystem in Gujarat

-

Skilled workforce in castor chemistry

-

Port connectivity for global exports

For international buyers, this means reliable origin sourcing, scalable volumes, and technical continuity.

Gujarat’s Role in Castor-Based Manufacturing

Gujarat functions as the processing and export backbone of India’s castor industry. Manufacturers located here benefit from:

-

Proximity to raw material

-

Integrated oil and derivative facilities

-

Established export compliance systems

Companies like Nova Industries operate within this ecosystem, enabling farm-to-export traceability and consistent industrial supply.

Quality, Compliance, and Documentation in Castor Oil Supply

For global buyers, quality is not limited to chemistry alone. It includes documentation, traceability, and shipment reliability.

Standard Buyer Expectations

-

Batch-wise Certificate of Analysis (COA)

-

MSDS / TDS availability

-

Controlled testing (acid value, moisture, appearance)

-

Stable packaging and labeling

-

Consistent export documentation

Suppliers meeting these expectations integrate manufacturing discipline with trade compliance, reducing buyer-side operational risk.

Castor Oil Derivatives and Sustainable Industrial Chemistry

Castor oil derivatives align naturally with bio-based and renewable material strategies. Unlike food oils, castor is:

-

Non-edible

-

Grown on marginal land

-

High-yield per hectare

This makes castor chemistry increasingly relevant for industries transitioning toward sustainable, plant-derived raw materials without sacrificing performance.

Conclusion

Castor oil and its derivatives form a strategic class of industrial materials—not commodities, but function-driven inputs essential to modern formulations.

Understanding:

-

Why derivatives exist

-

How they are produced

-

Where they are best sourced

allows global buyers to build stable, long-term supply chains with technically aligned manufacturers.

India—and Gujarat in particular—continues to be the global anchor for this value chain, supporting consistent, export-ready supply for international industries.

Technical & Commercial Enquiries

For datasheets, samples, or sourcing discussions related to castor oil and its derivatives, buyers may contact Nova Industries at export@novaind.in.