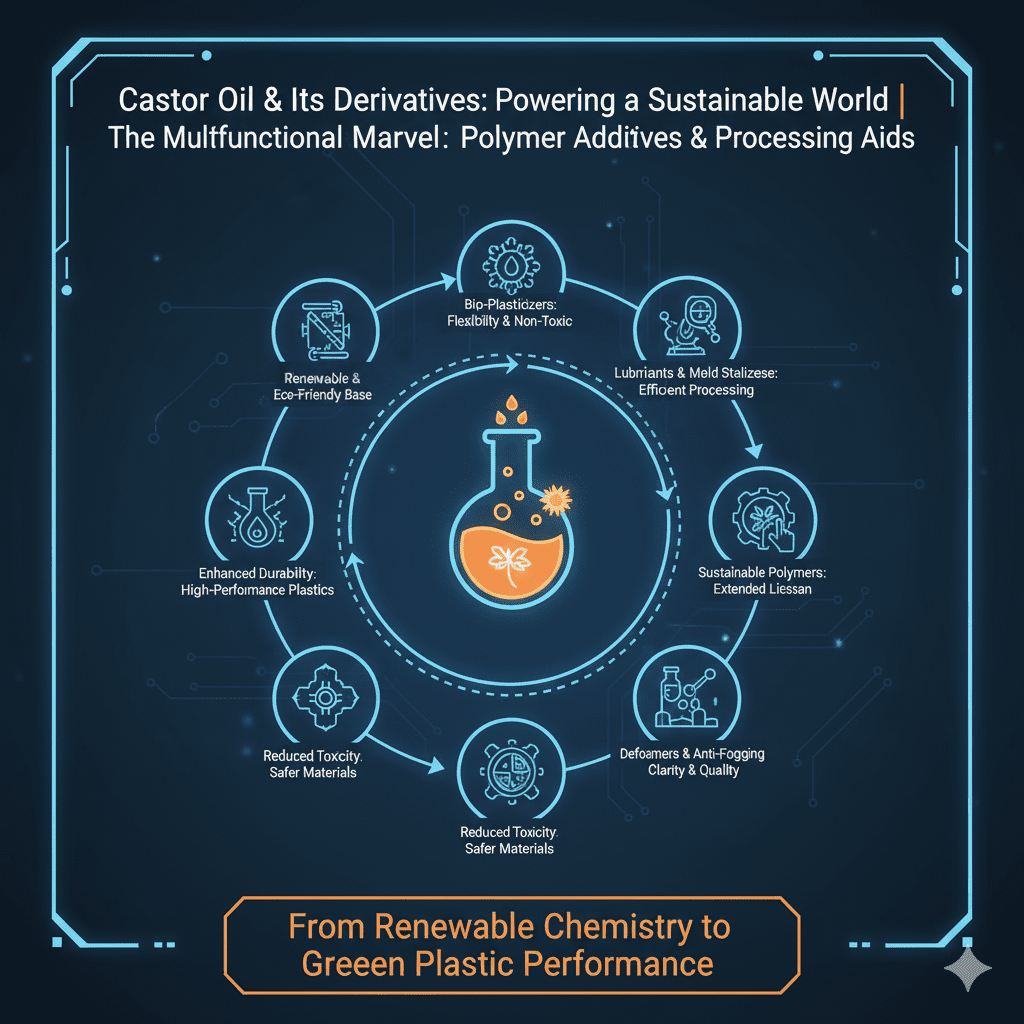

Summary: This article will uncover the unsung hero role of castor oil derivatives as multifunctional additives and processing aids within the broader polymer industry. While not always forming the main structure of a plastic, these bio-based compounds are crucial for enhancing the performance, durability, and manufacturability of a vast array of polymeric materials. This includes their use as environmentally friendly plasticizers that improve flexibility and reduce brittleness, as internal and external lubricants that facilitate molding and extrusion, as heat and light stabilizers that extend product lifespan, and as anti-fogging or defoaming agents. The article will highlight how these castor-based additives effectively replace many petroleum-derived and potentially hazardous alternatives, significantly contributing to the sustainability profile of everything from PVC and polyurethanes to rubbers and composites, making plastics greener from the inside out.

Key Points:

- The widespread use and environmental concerns of conventional polymer additives (e.g., phthalate plasticizers).

- Castor-based plasticizers: offering flexibility, durability, and non-toxicity to various polymers (e.g., PVC, bioplastics).

- Role as lubricants and mold release agents in polymer processing, improving efficiency and reducing energy.

- Use as heat and light stabilizers, extending the service life of plastic products and reducing material degradation.

- Application as anti-fogging agents in packaging films and defoamers in polymer production.

- Advantages: renewability, biodegradability of some forms, lower toxicity profile, compliance with green product standards.

- Contribution to enhancing the performance and longevity of plastic products while minimizing environmental impact.

- Driving innovation in sustainable polymer formulation and processing, making the plastic industry more circular.