First Pressed Degummed Castor Oil (FPD) – High-Purity Industrial Castor Oil | Nova Industries

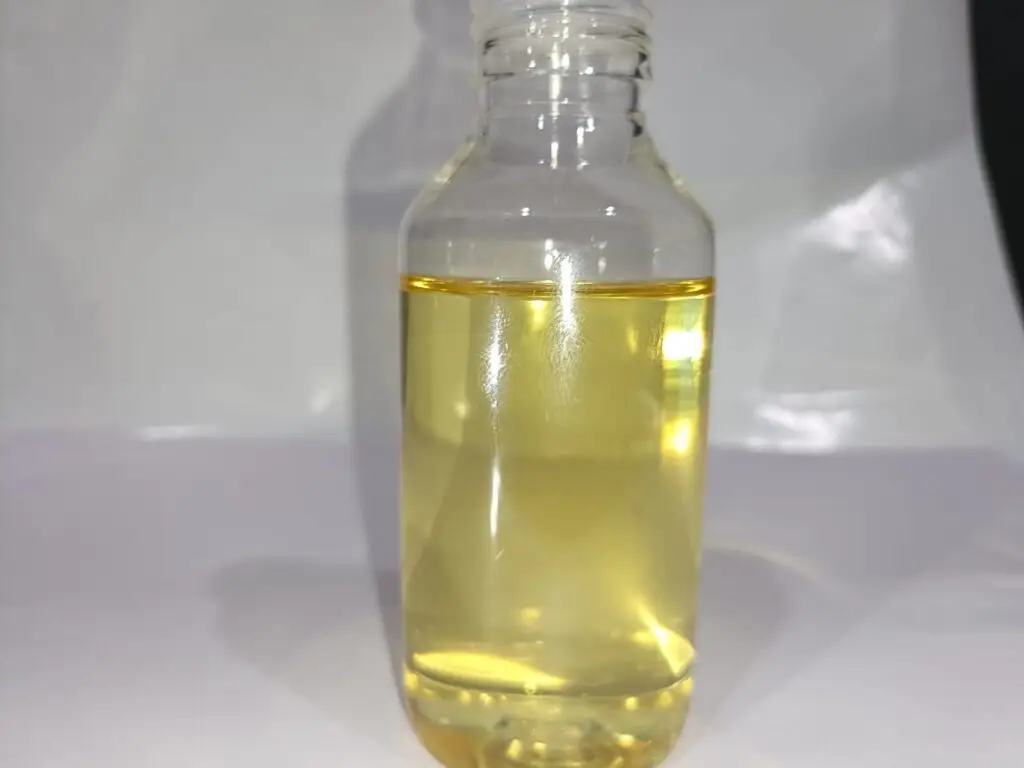

First Pressed Degummed Castor Oil (FPD) is a premium-quality grade derived from the very first pressing of clean castor seeds and further processed through advanced degumming techniques to remove gums, waxes, phospholipids, and impurities. This results in a high-purity, light-color, and superior-performance castor oil widely used in specialty chemicals, lubricants, coatings, adhesives, cosmetics, and many industrial formulations where purity and stability are critical.

Nova Industries is a globally trusted manufacturer of FPD Castor Oil, delivering consistent quality, strong performance characteristics, and strict compliance with international standards.

1. Manufacturing Process of First Pressed Degummed Castor Oil (FPD)

A. Seed Cleaning & Grading

-

Mature, high-oil-content castor seeds are sourced.

-

Seeds are cleaned to remove dust, stones, husk, and foreign materials.

-

Quality parameters checked:

-

Moisture level

-

Oil content

-

Purity

-

B. First Mechanical Pressing

-

Seeds undergo first pressing (cold pressed) to extract high-quality pale oil.

-

First-pressed oil naturally has lower impurities and better color.

C. Heated Conditioning (Optional)

-

Light heating enhances oil flow.

-

Ensures consistent pressing without degrading quality.

D. Primary Filtration

-

Removes:

-

Insoluble impurities

-

Dust particles

-

Seed hull sediments

-

E. Degumming Process

The key step that differentiates FPD from other grades.

-

Degumming removes:

-

Phospholipids

-

Plant gums

-

Waxes

-

Protein residues

-

-

Techniques used:

-

Water degumming

-

Acid-assisted degumming (mild phosphoric or citric acid)

-

Centrifugal separation

-

F. Settling & Polishing Filtration

-

Natural settling tanks ensure phase separation.

-

Multi-stage fine filtration gives crystal-clear, high-purity oil.

G. Quality Control

Each batch is tested for:

-

Acid value

-

Iodine value

-

Color (Lovibond)

-

Moisture content

-

Hydroxyl value

-

Insoluble impurities

-

Viscosity

H. Packaging

-

Packed in MS drums, HDPE drums, IBC tanks, or ISO tanks for export.

2. Applications & Industries Using First Pressed Degummed Castor Oil (FPD)

FPD is preferred where low impurities, light color, and high chemical reactivity are required.

A. Major Industries

-

Lubricants & grease manufacturers

-

Polyurethane & chemical intermediates

-

Paints, coatings & varnishes

-

Adhesive & sealant industry

-

Cosmetic & personal care

-

Textile auxiliaries

-

Printing ink & pigment dispersions

-

Leather chemicals

-

Polymer & plasticizer industries

B. Key Applications

-

High-performance lubricant formulations

-

Polyol and polyurethane intermediates

-

Alkyd resin production

-

Transparent coatings

-

Metalworking fluids

-

Hair and skincare products

-

Rubber processing aids

-

Wetting agents & surfactants

-

Bio-based additives

-

Industrial chemicals & esterification raw materials

FPD offers better reactivity and purity, making it ideal for high-end manufacturing applications.

3. Benefits of FPD Castor Oil

Functional Benefits

-

Higher purity due to degumming

-

Consistent, stable performance in formulations

-

Lower impurities → longer shelf life

Technical Benefits

-

Excellent chemical reactivity for:

-

Esterification

-

Hydrogenation

-

Polymerization

-

-

Very low phospholipid content

-

High hydroxyl value for derivative production

Commercial Benefits

-

Cost-effective compared to fully refined grades

-

High demand from multiple global industries

-

Better performance than ordinary commercial grades

4. Technical & Premium Quality Details

Premium First Pressed Degummed Castor Oil meets strict technical standards.

Typical Technical Parameters

-

Color (Lovibond): 2–4 (light color)

-

Moisture: ≤ 0.25%

-

Acid Value: 1–4 mg KOH/g

-

Saponification Value: 177–185

-

Iodine Value: 82–90

-

Hydroxyl Value: 160–168

-

Viscosity @ 25°C: 600–900 cP

-

Impurities: Less than 0.02% due to degumming

-

Ricinoleic Acid: 85–90%

-

Specific Gravity: 0.952–0.964

Quality Highlights

-

Low FFA levels

-

Low moisture content

-

Excellent clarity

-

Very low gum/phospholipid content

-

Consistent batch quality

5. Key Specifications & Features

Physical Features

-

Pale yellow, bright, clear liquid

-

Smooth viscosity

-

Mild scent

-

High purity

Chemical Features

-

Hydroxyl-rich fatty acid profile

-

Low gum, wax, and phospholipid content

-

Better chemical stability than CCO or non-degummed first-press oils

Available Forms

-

Standard FPD

-

Light-color FPD

-

Cosmetic/industrial customized grades (as required)

6. Why Choose Nova Industries for FPD Castor Oil

Nova Industries is recognized worldwide for its technical precision, stable quality, and ethical manufacturing of castor-based products.

A. Advanced Manufacturing Excellence

-

First-press extraction

-

Automated degumming units

-

Modern filtration systems

-

Contamination-free processing environment

B. Strict Quality Control

-

GC & HPLC analysis

-

Lovibond color checks

-

Moisture analyzer

-

Batch-wise viscosity and hydroxyl value testing

-

Full traceability

C. Certifications & Compliance

-

ISO-certified production

-

REACH-compliant for EU supply

-

FDA-aligned processes

-

Vegan, cruelty-free & GMO-free ingredients

D. Global Client Trust

-

Long-term customers in:

-

USA

-

Europe

-

Japan

-

Korea

-

Middle East

-

Latin America

-

-

Strong supply chain & predictable delivery timelines

E. Technical Expertise

-

Support for industrial formulations

-

Custom-made specifications

-

Integrated production of derivatives (12HSA, HCO, etc.)

7. Environmental & Sustainability Points

FPD is a highly sustainable and eco-friendly product.

Renewable Source

-

Derived from castor seeds → 100% renewable raw material

-

Non-edible crop grown in dry regions

Eco-Friendly Production

-

Low environmental impact

-

No deforestation required

-

Minimal water usage

Biodegradability

-

Fully biodegradable

-

Safe alternative to synthetic petrochemical oils

Green Chemistry Advantages

-

Promotes bio-based chemical industry

-

Low carbon emissions

-

Ideal for sustainable product lines

8. High-Performance Characteristics

-

Excellent oxidative stability

-

Strong film-forming properties

-

High viscosity stability under temperature stress

-

Good lubricity for industrial applications

-

Low impurities improve performance in:

-

Polyols

-

Resins

-

Adhesives

-

Coating formulations

-

Due to degumming, the oil provides superior reactivity and efficiency in chemical production.

9. Additional Value-Added Information

A. Packaging Options

-

180–200 kg MS drums

-

180 kg HDPE drums

-

1000-liter IBC tanks

-

20–22 MT ISO tanks

-

Flexi-tanks for bulk shipment

B. Storage Guidelines

-

Store in cool, dry area

-

Keep containers sealed

-

Avoid direct sunlight

-

Ideal temperature: 20–30°C

C. Shelf Life

-

24 months if stored properly

D. Safety & Handling

-

Non-toxic and safe

-

Wear gloves during handling

-

Avoid eye contact

-

Follow standard industrial hygiene practices

E. Export Advantages

-

India is world’s No.1 castor oil exporter

-

Strong global demand for high-quality degummed grades

-

Ready shipments via Mundra Port

F. Global Market Trends

-

Rising use in bio-based lubricants

-

Growth in polyurethane industry

-

Increasing shift from petroleum derivatives to natural oils