Methyl 12-Hydroxy Stearate (Methyl 12HSA) is a hydroxylated fatty acid methyl ester derived from castor oil. It combines the ester functionality with a hydroxyl group on the carbon chain, giving it controlled reactivity, good compatibility, and predictable processing behavior.

Industrially, Methyl 12HSA is used as a functional intermediate and performance additive in systems where flow control, lubrication, and chemical modification are required.

Product Overview

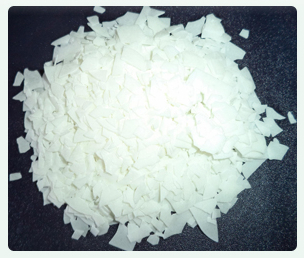

Methyl 12HSA originates from castor oil obtained from Ricinus communis. The product is typically supplied as a solid (flakes or pastilles), depending on processing and handling requirements.

Common industrial forms:

-

Flakes

-

Pastilles / granules (application dependent)

At a high level, Methyl 12HSA is produced by esterifying 12-hydroxy stearic acid. Compared with free fatty acids, the methyl ester form offers improved handling, controlled polarity, and better compatibility in selected formulations, particularly where acidity must be minimized.

Manufacturing Process (High Level)

The manufacturing of Methyl 12-Hydroxy Stearate follows a standardized, high-level pathway.

1. Raw Material Sourcing

12-Hydroxy stearic acid derived from hydrogenated castor oil is used as the primary feedstock.

2. Esterification

The fatty acid is converted into its methyl ester through controlled esterification.

3. Purification & Refining

Residual reactants and impurities are removed to achieve consistent quality.

4. Solidification & Finishing

The product is solidified and processed into flakes or granules suitable for industrial use.

5. Quality Control Stages

-

Incoming raw material inspection

-

In-process monitoring

-

Final batch testing prior to packing

No proprietary temperatures, catalysts, or confidential processing details are disclosed.

Key Properties & Technical Characteristics

The performance of Methyl 12HSA depends on its physical form and chemical structure. Each parameter influences formulation behavior.

-

Appearance & Physical State – White to off-white solid; uniform appearance indicates controlled processing.

-

Odour – Mild characteristic odour; suitable for formulation-sensitive uses.

-

Melting Behavior – Defined melting range supports predictable processing.

-

Acid Value – Very low compared with free fatty acids, indicating effective esterification.

-

Hydroxyl Value – Confirms presence of hydroxyl functionality for downstream reactions.

-

Moisture Content – Low moisture enhances stability and shelf life.

-

Unsaponifiable Matter – Controlled to maintain formulation consistency.

-

Chemical Stability – Supports storage and transport under recommended conditions.

-

Typical Impurities Monitored – Residual alcohols, unreacted acids, particulates.

Typical Technical Parameters

| Parameter | Typical Indication |

|---|---|

| Appearance | White to off-white solid |

| Key Chemical Values | Typical range — confirm with Certificate of Analysis (COA) |

| Melting Characteristics | Application-dependent |

Exact numerical values vary by grade and must be confirmed with the COA.

Applications & End-Use Industries

Pharmaceuticals

Use case: Functional intermediate and processing aid.

Why it works: Low acidity and controlled reactivity.

Examples: Excipient systems, formulation intermediates.

Cosmetics & Personal Care

Use case: Texture and performance modifier.

Why it works: Smooth feel and compatibility with oil phases.

Examples: Creams, lotions, specialty personal care formulations.

Lubricants & Greases

Use case: Lubricity and flow modifier.

Why it works: Ester structure provides lubricating properties with stability.

Examples: Specialty lubricants, grease systems.

Polymers & Resins

Use case: Renewable chemical intermediate.

Why it works: Hydroxyl functionality enables chemical modification.

Examples: Polyurethane intermediates, specialty resins.

Paints, Coatings & Adhesives

Use case: Processing and performance additive.

Why it works: Improves flow and compatibility in resin systems.

Examples: Industrial coatings, adhesive formulations.

Specialty & Other Industrial Uses

Use case: Intermediate for further chemical synthesis.

Why it works: Predictable structure and reactivity.

Examples: Specialty esters, performance additives.

Quality Standards & Compliance Practices

Methyl 12HSA is supplied based on testing discipline and batch verification, not unverifiable certification claims.

Common practices include:

-

Acid value testing

-

Moisture analysis

-

Appearance and odour checks

-

Batch traceability

-

Availability of COA, TDS, and MSDS

-

Quality systems aligned with generic ISO-style frameworks

Packaging, Storage & Export Handling

Common packaging options:

-

HDPE bags with inner liner

-

Fiber drums

-

Bulk packaging (application dependent)

Storage guidelines:

-

Store in a cool, dry, sealed environment

-

Protect from moisture and contamination

-

Shelf life depends on storage conditions

Export documentation typically includes:

-

Commercial Invoice

-

Packing List

-

Certificate of Analysis (COA)

-

MSDS

-

Bill of Lading

HS Code: Provided on request

MOQ & Lead Time: Subject to grade, packaging, and incoterms; confirm at enquiry

Why Buyers Source Methyl 12HSA from India

India is a primary origin for castor oil and castor-based derivatives. Gujarat functions as a key processing and export hub due to integrated agricultural sourcing, established chemical manufacturing infrastructure, and strong port connectivity, supporting traceable and consistent global supply.

Frequently Asked Questions (FAQs)

1. What is Methyl 12HSA mainly used for?

As an intermediate and performance additive in industrial formulations.

2. How does it differ from 12-hydroxy stearic acid?

It is esterified, resulting in lower acidity and different handling characteristics.

3. Is it water-soluble?

No, it is insoluble in water.

4. How should it be stored?

In sealed containers, away from heat and moisture.

5. What affects shelf life?

Storage conditions and exposure to moisture.

6. Are batches tested before dispatch?

Yes, routine QC checks are performed.

7. Are different grades available?

Grades may vary based on application requirements.

8. Is export documentation provided?

COA, MSDS, and standard export documents are available.

Technical Enquiries

For technical datasheets, samples, or commercial enquiries, buyers may contact Nova Industries at export@novaind.in.