Dehydrated Castor Oil (DCO) is a modified vegetable oil produced by controlled dehydration of refined castor oil derived from Ricinus communis. The dehydration process increases the level of conjugated unsaturation, making DCO a reactive, film-forming oil used widely in industrial coatings, inks, and resin systems where drying behavior and compatibility are important.

Globally, DCO serves as a functional intermediate rather than a finished consumer product.

Product Overview

DCO originates from castor oil obtained from castor seeds (Ricinus communis). Through dehydration, the natural hydroxyl functionality is transformed to create conjugated double bonds, which enhance drying and polymerization behavior.

Common industrial forms and grades:

- Standard Dehydrated Castor Oil

- Variants tailored for coating and resin systems (grade dependent)

At a high level, DCO is produced via dehydration followed by refining and filtration. Compared with non-modified castor oil, DCO offers improved drying characteristics and film hardness, making it suitable for surface-coating applications.

Manufacturing Process (High Level)

The industrial production of Dehydrated Castor Oil follows a controlled, high-level pathway.

1. Raw Material Sourcing

Refined castor oil sourced from castor seeds is used as the base feedstock.

2. Dehydration Reaction

The oil undergoes controlled dehydration to create conjugated unsaturation responsible for drying behavior.

3. Refining & Finishing

Post-reaction refining removes residual impurities and stabilizes the oil.

4. Filtration & Packaging

The finished oil is filtered and prepared for packaging or downstream processing.

5. Quality Control Stages

- Incoming raw material inspection

- In-process monitoring

- Final batch testing before dispatch

No proprietary temperatures, catalysts, or confidential processing details are disclosed.

Key Properties & Technical Characteristics

DCO’s performance depends on its chemical structure and stability. Each property affects formulation and end-use behavior.

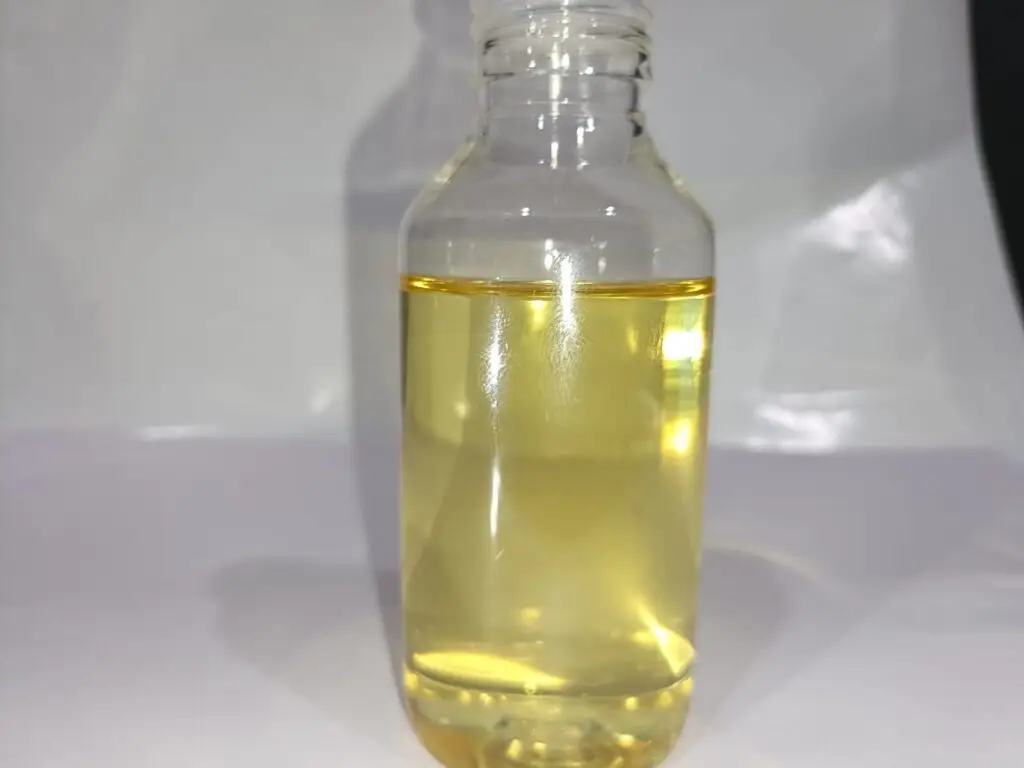

- Appearance & Physical State – Clear to amber liquid; visual clarity indicates effective refining.

- Odour – Mild characteristic odour; relevant for coatings and inks.

- Viscosity – Influences flow, application, and film thickness.

- Specific Gravity – Reflects composition consistency between batches.

- Acid Value – Indicates free fatty acid content and oil quality.

- Iodine Value – Higher than native castor oil due to conjugated unsaturation.

- Saponification Value – Used to assess fatty acid composition.

- Moisture Content – Low moisture supports storage stability.

- Unsaponifiable Matter – Controlled to ensure formulation consistency.

- Drying Behavior – Enables film formation through oxidation/polymerization.

- Typical Impurities Monitored – Residual gums, particulates, trace contaminants.

Typical Technical Parameters

| Parameter | Typical Indication |

|---|---|

| Appearance | Clear to amber liquid |

| Key Chemical Values | Typical range — confirm with Certificate of Analysis (COA) |

| Drying Characteristics | Application-dependent |

Exact numerical values vary by grade and must be confirmed with the COA.

Applications & End-Use Industries

Pharmaceuticals

Use case: Limited, formulation-specific intermediate.

Why it works: Chemical stability when properly refined.

Examples: Specialty excipient systems (application dependent).

Cosmetics & Personal Care

Use case: Restricted, formulation-dependent use.

Why it works: Film-forming nature in niche applications.

Examples: Specialized cosmetic formulations.

Lubricants & Greases

Use case: Modifier in specialty lubricant systems.

Why it works: Reactive structure and compatibility with additives.

Examples: Industrial lubricant blends.

Polymers & Resins

Use case: Reactive oil component.

Why it works: Conjugated unsaturation supports polymerization.

Examples: Alkyd resins, modified resin systems.

Paints, Coatings & Adhesives

Use case: Film-forming and drying oil.

Why it works: Enhanced drying and hardness development.

Examples: Industrial paints, varnishes, printing inks.

Specialty & Other Industrial Uses

Use case: Intermediate for further chemical modification.

Why it works: Predictable chemical reactivity.

Examples: Modified oils and specialty coatings.

Quality Standards & Compliance Practices

DCO is supplied based on testing discipline and batch verification, not unverifiable certification claims.

Common practices include:

- Acid value testing

- Moisture analysis

- Appearance and odour checks

- Batch traceability

- Availability of COA, TDS, and MSDS

- Quality systems aligned with generic ISO-style frameworks

Packaging, Storage & Export Handling

Common packaging formats:

- HDPE drums

- IBC containers

- Bulk supply (application dependent)

Storage guidelines:

- Store in a cool, dry, sealed environment

- Protect from heat, air exposure, and moisture

- Shelf life depends on storage conditions

Export documentation typically includes:

- Commercial Invoice

- Packing List

- Certificate of Analysis (COA)

- MSDS

- Bill of Lading

HS Code: Provided on request

MOQ & Lead Time: Subject to grade, packaging, and incoterms; confirm at enquiry

Why Buyers Source Dehydrated Castor Oil from India

India is a major origin for castor oil and its derivatives due to established agricultural supply chains and processing infrastructure. Gujarat functions as a key manufacturing and export hub, supporting traceability, consistent quality, and global shipment capability.

Frequently Asked Questions (FAQs)

1. What is DCO mainly used for?

Primarily in coatings, inks, and resin systems.

2. How does DCO differ from regular castor oil?

It has conjugated unsaturation that enables drying and film formation.

3. Is DCO water-soluble?

No, it is insoluble in water.

4. How should DCO be stored?

In sealed containers, away from heat and moisture.

5. What affects shelf life?

Storage conditions and exposure to air.

6. Are batches tested before dispatch?

Yes, routine QC checks are performed.

7. Are different grades available?

Grades may vary depending on application needs.

8. Is export documentation provided?

COA, MSDS, and standard export documents are available.

Technical Enquiries

For technical datasheets, samples, or commercial enquiries, buyers may contact Nova Industries at export@novaind.in.