Hydrogenated Castor Oil (HCO) – Flakes, also known as Castor Wax, is a chemically modified derivative of castor oil produced through controlled hydrogenation. It is widely used across pharmaceuticals, cosmetics, lubricants, polymers, coatings, and specialty chemicals where high melting point, excellent hardness, oxidative stability, and consistency are required.

This article presents a neutral, technical, EEAT-compliant overview of Hydrogenated Castor Oil – Flakes, covering product fundamentals, high-level manufacturing, key properties, industrial applications, quality expectations, packaging, export considerations, and buyer FAQs for global industrial sourcing teams.

Product Overview

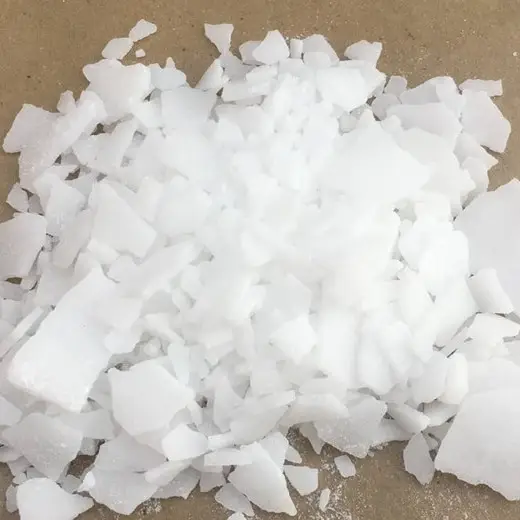

Hydrogenated Castor Oil – Flakes is a solid, wax-like material obtained by hydrogenating refined castor oil to convert unsaturated bonds into saturated ones. The result is a hard, brittle solid supplied in flake form for ease of handling and dosing.

Common names & references

-

Hydrogenated Castor Oil (HCO)

-

Castor Wax

-

Hydrogenated Ricinoleic Triglyceride

Feedstock & processing (high level)

The product originates from castor seeds (Ricinus communis). Refined castor oil undergoes hydrogenation, which significantly improves thermal stability, hardness, and resistance to oxidation.

Key differentiators vs liquid castor oil

-

Solid physical form with high melting point

-

Improved oxidative and thermal stability

-

Non-drying, non-yellowing behavior

-

Better performance in high-temperature and structural applications

Buyer-focused benefit

HCO Flakes are chosen when formulations require structure, rigidity, controlled melting behavior, and long-term stability without compromising renewable content.

Manufacturing Process (High-Level Overview)

This section is intentionally non-confidential and industry-standard.

-

Raw material preparation

High-purity refined castor oil is used as the base feedstock to ensure consistent hydrogenation results. -

Hydrogenation reaction

The oil is reacted with hydrogen in the presence of a catalyst, converting unsaturated fatty chains into saturated structures. This raises the melting point and improves stability. -

Post-processing & finishing

The hydrogenated mass is filtered to remove catalyst residues, solidified, and mechanically processed into uniform flakes. -

Quality control checkpoints

-

Incoming oil verification

-

Monitoring hydrogenation completion

-

Final testing before flaking and packing

-

This controlled process ensures batch-to-batch uniformity, which is critical for industrial formulations.

Key Properties & Technical Characteristics

Hydrogenated Castor Oil – Flakes is evaluated on the following technical parameters. Numeric values should always be verified against the supplier’s COA.

-

Physical state & appearance

White to off-white solid flakes; appearance impacts cosmetic and coating clarity. -

Odour

Practically odourless, making it suitable for sensitive formulations. -

Melting point

High melting point provides hardness and thermal resistance in end products. -

Hardness & brittleness

Important for wax blends, polishes, and structural applications. -

Acid value

Indicates residual free fatty acids; lower values support better stability. -

Iodine value

Very low, reflecting high saturation and excellent oxidation resistance. -

Saponification value

Relevant for soap, surfactant, and ester-based formulations. -

Hydroxyl value

Retained functionality supports chemical compatibility in resins. -

Moisture & ash content

Low levels are essential for shelf life and process reliability.

Buyer note: Publish a table of “Typical Specifications” and mark all values as typical — verify with COA unless supported by lab-certified data.

Applications & End-Use Industries

Pharmaceuticals

HCO Flakes are used as a binder, stiffening agent, and release modifier in solid dosage forms.

Why chosen: high purity, inertness, and thermal stability.

Examples: tablet coatings, sustained-release systems, ointment bases.

Cosmetics & Personal Care

Functions as a structuring wax and consistency enhancer.

Why chosen: plant-derived, stable, and compatible with oils and esters.

Examples: lipsticks, creams, deodorant sticks, balms.

Lubricants & Greases

Used as a thickener and structure builder.

Why chosen: high dropping point and resistance to oxidation.

Examples: specialty greases, high-temperature lubricants.

Polymers & Resins

Acts as a modifier and processing aid.

Why chosen: improves hardness, flow control, and surface properties.

Examples: polyamide resins, hot-melt adhesives, elastomers.

Paints, Coatings & Inks

Provides rheology control and matting effects.

Why chosen: non-yellowing and chemical stability.

Examples: industrial coatings, printing inks, varnishes.

Other Industrial Uses

Includes polishes, carbon paper, textiles, and specialty chemical intermediates.

Quality Standards & Specifications

Typical quality evaluation includes:

-

Melting point

-

Acid value

-

Iodine value

-

Hydroxyl value

-

Moisture content

-

Ash content

-

Catalyst residue (where applicable)

Traceability & documentation

-

Batch-wise COA

-

TDS and MSDS

-

Batch identification and retention samples

Certifications (ISO, GMP, cosmetic compliance) must be stated only if valid and verifiable.

Packaging, Storage & Export Supply

Packaging options

-

20–25 kg HDPE-lined bags or cartons

-

Jumbo bags for bulk supply

-

Custom packaging on request

Storage & shelf life

-

Store in a cool, dry place, away from heat and moisture

-

Keep packaging tightly sealed

-

Shelf life depends on storage conditions; verify via COA

Export handling

-

HS code: to be confirmed based on destination

-

Standard export documents: Commercial Invoice, Packing List, COA, MSDS, Bill of Lading/AWB, Certificate of Origin if required

-

MOQ and lead time depend on order size and Incoterms

Why Global Buyers Source HCO from India

India is the largest global producer of castor seeds, and Gujarat is a major hub for castor oil processing and hydrogenation. Buyers source from India due to:

-

Reliable access to raw materials

-

Established hydrogenation expertise

-

Integrated processing clusters

-

Strong export logistics and port connectivity

-

Competitive pricing with scalable volumes

Indian suppliers increasingly emphasize traceability, batch control, and export compliance.

FAQs

1. What is Hydrogenated Castor Oil used for?

It is used as a wax, thickener, binder, and stabilizer across pharma, cosmetics, lubricants, and polymers.

2. Is HCO the same as Castor Wax?

Yes, Castor Wax is a common industry name for hydrogenated castor oil.

3. What packaging sizes are available?

Typically 20–25 kg bags; bulk options available on request.

4. What is the shelf life?

Shelf life depends on storage; refer to COA and MSDS.

5. Is pharma or cosmetic grade available?

Only if the supplier holds appropriate GMP or cosmetic compliance—verify documentation.

6. Does HCO oxidize easily?

No. Due to hydrogenation, it has excellent oxidative stability.

7. What documents are provided?

COA, TDS, MSDS, and Certificate of Origin (if required).

8. Can custom flake size be supplied?

Possible, subject to agreement and order volume.

Buyer-Focused Closing

Hydrogenated Castor Oil – Flakes is a versatile, renewable wax material selected for stability, structure, and consistent performance. Buyers should always validate specifications and documentation against intended end-use requirements.

Supplier reference:

Nova Industries — Manufacturer & exporter of castor oil and derivatives, Gujarat, India.

COA, TDS, and MSDS are available on request.