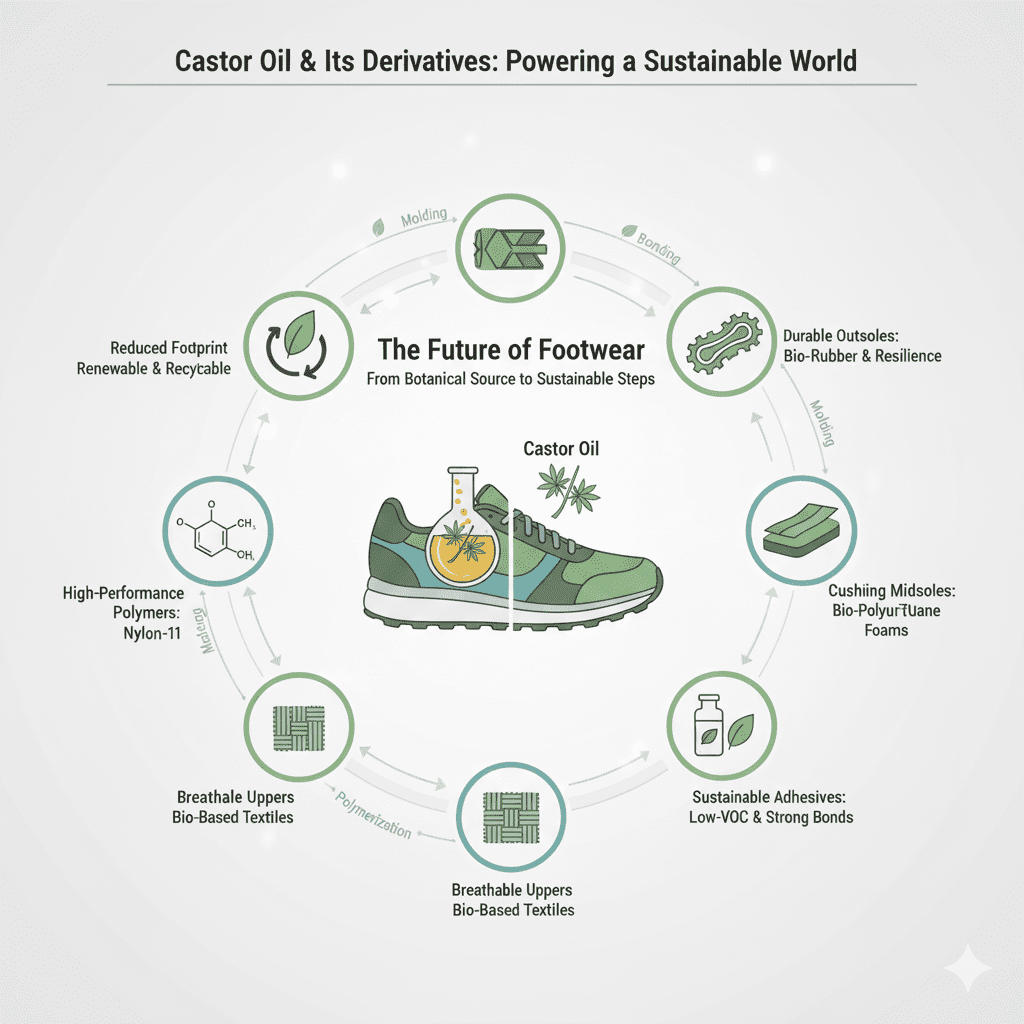

Summary: This article will take a close look at how castor oil derivatives are profoundly influencing the footwear industry’s stride towards sustainability. Traditionally reliant on synthetic rubbers and plastics derived from fossil fuels, shoe manufacturing faces significant environmental challenges. Castor-based polyols and polyamides (like Nylon-11) are now being innovatively integrated into the creation of high-performance, eco-friendly shoe components. This includes durable and lightweight outsoles, cushioning midsoles, breathable upper materials, and sustainable adhesives. The article will highlight how these renewable materials contribute to reducing the carbon footprint of footwear production, offering enhanced performance characteristics (such as flexibility, impact absorption, and abrasion resistance), and providing consumers with more environmentally conscious choices for their everyday shoes, athletic gear, and outdoor footwear, truly shaping the future of sustainable steps.

Key Points:

- The environmental impact of conventional footwear manufacturing (petroleum-based materials, waste, chemical use).

- Castor-based polyols as key components in bio-polyurethane foams for comfortable and durable midsoles, offering excellent cushioning.

- High-performance bio-polyamides (Nylon-11) derived from castor oil for strong, lightweight outsoles, reinforcements, and technical upper materials.

- Use in sustainable, low-VOC adhesives and cements for bonding shoe components, reducing harmful emissions.

- Potential for bio-based leathers or synthetic leathers using castor derivatives.

- Advantages: renewability, reduced fossil fuel dependency, potential for improved biodegradability/recyclability of components.

- Contribution to lighter shoes, enhanced athletic performance, and extended product lifespan.

- Driving innovation in “green” footwear design and manufacturing, meeting consumer demand for eco-conscious fashion.