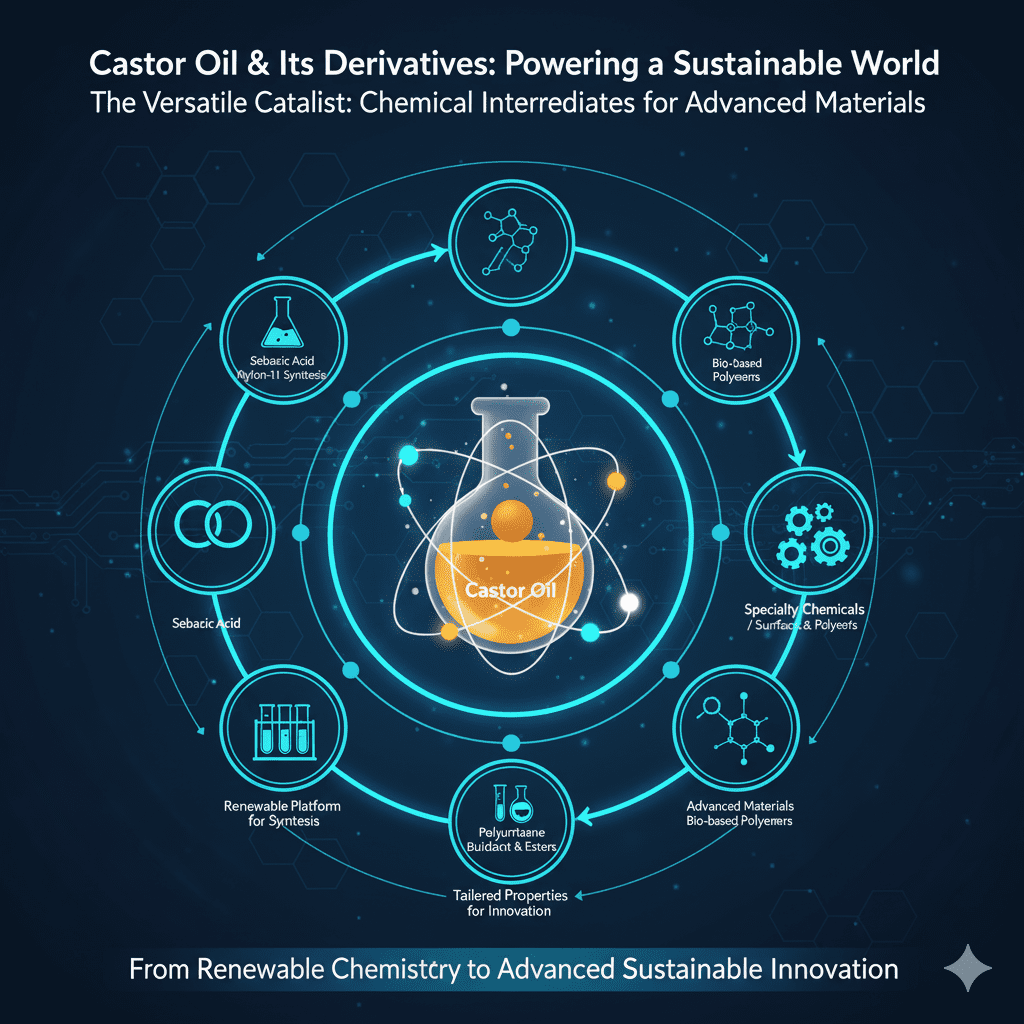

Summary: This article will delve into a fundamental and highly impactful, yet often unseen, role of castor oil derivatives: their function as versatile chemical intermediates and building blocks for synthesizing a vast array of other advanced materials. Rather than being the final product, many castor-derived compounds serve as crucial starting points for more complex chemical reactions. This includes the production of diacids like sebacic acid (essential for Nylon-11), polyols for custom polyurethane systems, and various fatty acid esters and amides that are further functionalized into high-value specialty chemicals. The article will highlight how castor oil’s unique structure provides a renewable platform for molecular engineering, enabling the creation of tailored materials with precise properties needed for cutting-edge applications in various industries, thereby acting as a “catalyst” for sustainable innovation throughout the chemical value chain.

Key Points:

- Definition of chemical intermediates and their importance in organic synthesis.

- The role of ricinoleic acid’s hydroxyl group and double bond in versatile chemical transformations.

- Production of sebacic acid from castor oil and its importance for polyamides (Nylon-11, Nylon-6,10).

- Synthesis of various castor-based polyols for custom-designed polyurethane foams, elastomers, and coatings.

- Creation of fatty acid esters and amides as precursors for surfactants, lubricants, and specialty polymers.

- Advantages of bio-based intermediates: reduced reliance on petroleum, lower carbon footprint in synthesis, potentially safer reaction pathways.

- Driving the shift towards a sustainable bio-based chemical industry by providing fundamental building blocks.

- Examples of advanced materials enabled by these intermediates in diverse sectors (e.g., aerospace, medical, automotive).