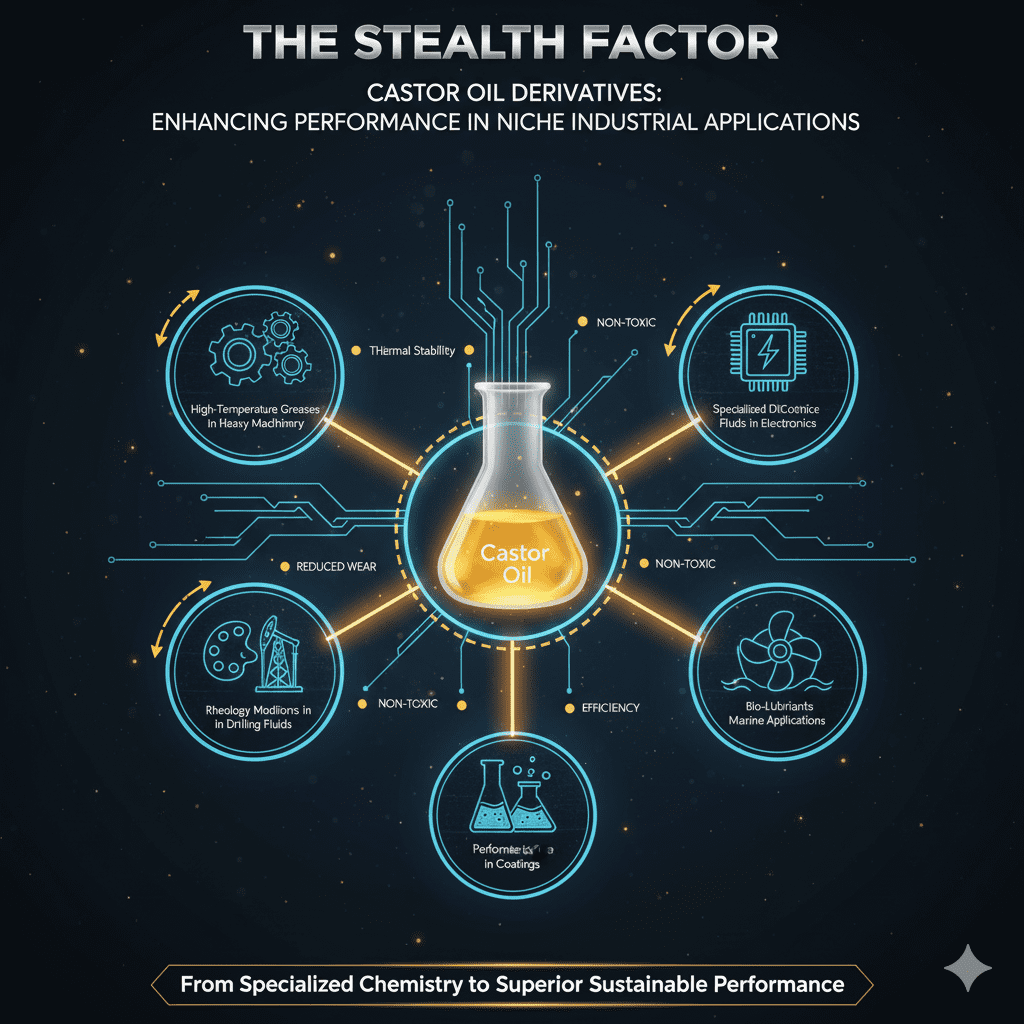

This article will uncover the often-unseen but vital roles that castor oil derivatives play in highly specialized and niche industrial applications, where their unique properties translate into significant performance enhancements and sustainability benefits. From high-temperature greases in heavy machinery to specialized dielectric fluids in electronics, or unique rheology modifiers in drilling fluids, castor-based compounds often outperform conventional materials. The focus will be on how their thermal stability, lubricity, polarity, and non-toxicity address specific technical challenges, leading to improved equipment longevity, operational efficiency, and a reduced environmental footprint in demanding industrial environments, proving that sustainability can also mean superior performance.

Key Points:

- Overview of industrial sectors with highly specific material requirements (e.g., aerospace, marine, heavy manufacturing).

- Castor derivatives as high-performance additives and base materials in specialized greases and lubricants for extreme conditions.

- Role in dielectric fluids for transformers or electronic components (e.g., sebacates).

- Use as rheology modifiers, dispersants, or defoamers in industrial processes (e.g., paints, construction chemicals, oil & gas drilling).

- Advantages: improved thermal stability, oxidation resistance, better adhesion, reduced volatility, non-toxicity.

- Contribution to operational efficiency, reduced maintenance, and extended equipment life cycles.

- Demonstrating that bio-based solutions are not just “green” but also technically superior in many critical applications.